In low-voltage power distribution, the Molded Case Circuit Breaker (MCCB) acts as the primary guardian against overloads and short circuits. However, the brain of this guardian—the trip unit—determines how effectively it protects your specific assets. Choosing between the robust simplicity of thermal-magnetic units and the high-precision intelligence of electronic units is a critical engineering decision that impacts cost, selectivity, and system reliability. MCCB thermal magnetic vs electronic selection is not just about price; it is about matching the protection curve to the load profile.

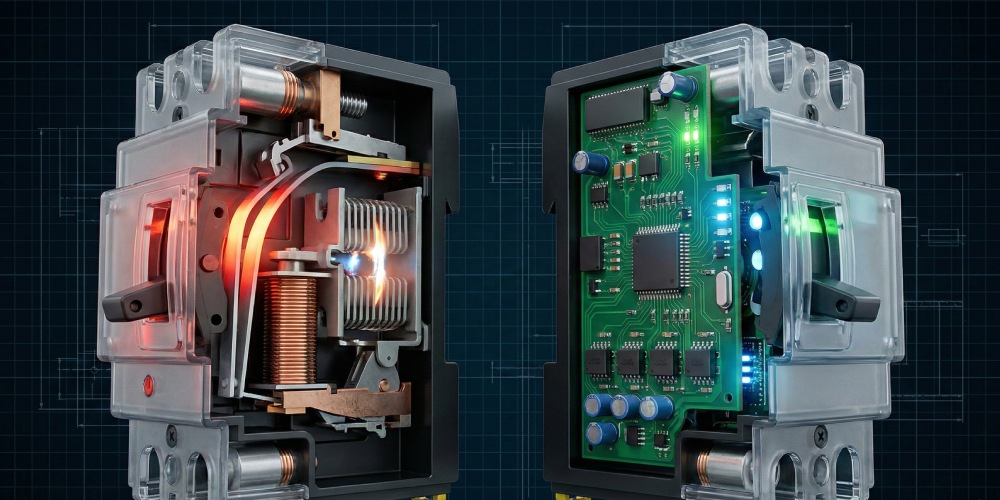

Thermal-magnetic breakers rely on physical laws (heat and magnetism) for protection. Electronic breakers rely on algorithms and microprocessors. Understanding this fundamental difference is the first step in designing safe and efficient electrical panels, from main distribution boards in factories to sub-distribution panels in residential complexes.

Thermal-Magnetic Trip Units: The Reliable Standard

Thermal-magnetic MCCBs use a dual-mechanism approach that has been the industry standard for decades. They offer a "fit-and-forget" reliability that makes them ideal for standard applications where complex adjustability is not required.

- Thermal Protection (Overload): A bimetallic strip heats up as current passes through it. If the current exceeds the rated limit for a specific time, the strip bends and unlatches the mechanism. This physical reaction provides a natural time-delay, perfect for handling harmless inrush currents.

- Magnetic Protection (Short Circuit): An electromagnet creates a magnetic field proportional to the current. In a short circuit event, this force becomes strong enough to instantaneously trip the breaker, cutting off the fault in milliseconds.

Best For: Standard building distribution, simple motor feeders, and cost-sensitive projects where high precision is not critical.

Electronic Trip Units: Precision and Intelligence

Electronic trip units replace the bimetal and coil with internal current transformers (CTs) and a microprocessor. This digital brain measures the current in real-time and executes protection algorithms with high accuracy. They are immune to ambient temperature changes, which can affect thermal-magnetic units.

- Adjustability: Electronic MCCBs offer wide adjustable ranges for Long Time (L), Short Time (S), and Instantaneous (I) protection settings. This allows engineers to fine-tune the breaker to the exact load requirements.

- Communication: Advanced models can transmit data (current, voltage, energy usage, fault history) to building management systems (BMS), turning the breaker into an energy monitoring device.

Best For: Main distribution panels, generators, complex industrial networks requiring strict selectivity, and environments with varying ambient temperatures.

Comparison Table: Matching Technology to Needs

|

Feature |

Thermal-Magnetic (TM) |

Electronic (Micrologic) |

|

Accuracy |

Good (Affected by ambient temp) |

High Precision (Temp independent) |

|

Adjustability |

Limited (Usually fixed or narrow range) |

Wide range (L, S, I, G settings) |

|

Response |

Physical/Mechanical |

Digital/Algorithmic |

|

Diagnostics |

None |

Fault history, Load monitoring |

|

Cost |

Cost-Effective |

Premium Investment |

|

Primary Use |

Sub-distribution, Lighting |

Main Switchboards, Critical Power |

Which Panel Needs Which?

Selecting the right MCCB depends heavily on the hierarchy of the panel within the electrical system.

Main Distribution Boards (MDB)

Recommendation: Electronic Trip Units. At the top of the hierarchy, selectivity (coordination) is paramount. You want the downstream breaker to trip first in case of a fault, keeping the main power on. Electronic units allow you to precisely delay the tripping time to ensure this coordination. They also provide valuable energy data for facility managers.

Sub-Distribution Panels

Recommendation: Thermal-Magnetic Trip Units. For panels feeding lighting circuits, standard HVAC units, or general power outlets, the precision of electronic units is often unnecessary. A thermal-magnetic MCCB provides robust protection at a better price point, making it the logical choice for downstream distribution.

2026 Vision: Smart Breakers and Predictive Maintenance

As we move toward 2026, electronic MCCBs are evolving into "Smart Circuit Breakers." Integrated with IoT capabilities, these devices will not just protect but predict. By analyzing current signatures, they will be able to warn facility managers about motor wear or insulation degradation before a fault occurs, shifting maintenance from reactive to proactive.